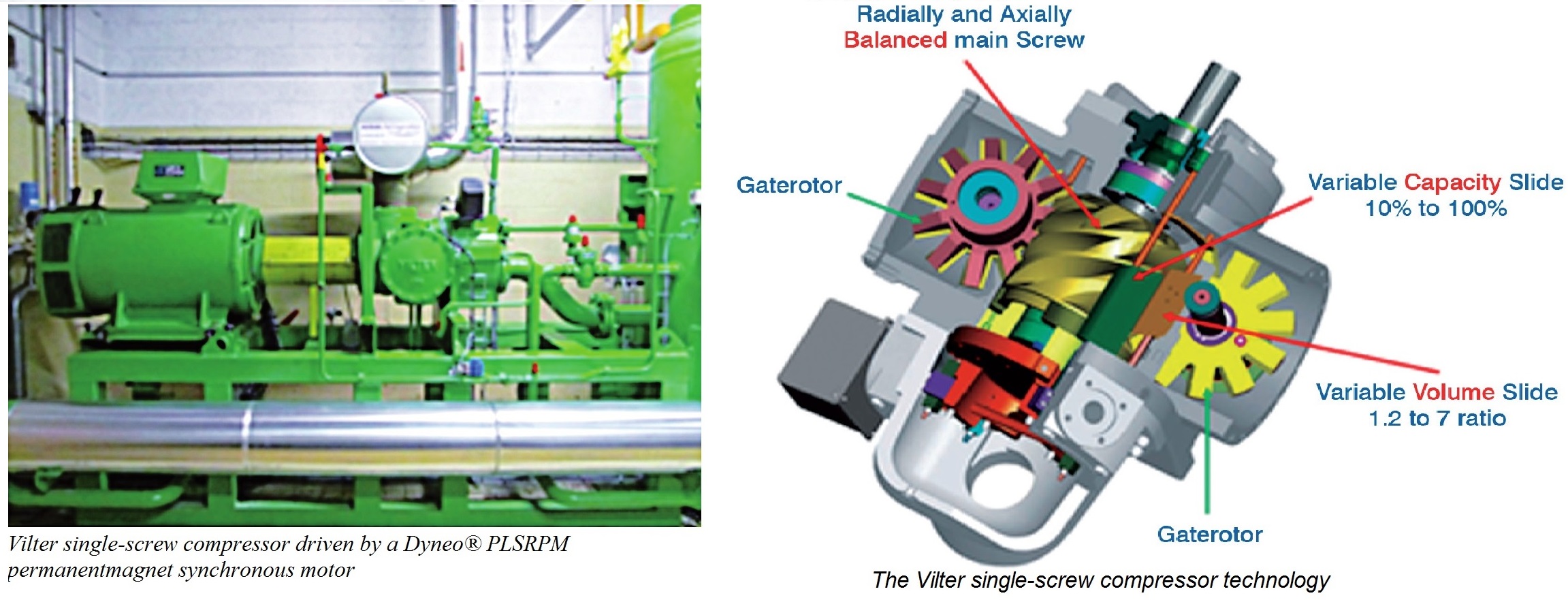

La Compagnie des Fromages is part of the Bongrain Group, the world’s fifth-largest milk-processing company and an employer of 18,870 people. Cofely Axima–GDF Suez, a leader in industrial refrigeration who designed their manufacturing facility, carried out an energy audit that, based on a series of measurements, provided a snapshot of the plant’s consumption levels and suggested replacing its four piston compressors, which provided only cooling, by a thermorefrigerating pump. A thermorefrigerating pump is a thermodynamic heat-transfer system that can cool and heat at the same time. The refrigeration system makes it possible to provide cooling capacity to the evaporator and heating capacity to the condenser. When 1000 kW of chilled water is produced at the plant, 1300 kW of energy is recovered at the same time and combined with just 100 kW of electricity to heat water to +62°C. All the energy produced and used is fully recovered. A 150 m3 buff er storage unit allows energy to be used to produce hot water as needed by the process (particularly cleaning operations). With the old system, this water was heated by gas, which has a much higher carbon footprint. In addition, the heat produced was rejected to the atmosphere by a cooling tower instead of being recovered and reused. The new system saves 9000 m3 of water a year and has reduced use of the cooling tower, which, with its plumes of steam, always reflects negatively with local residents. At the heart of the system are a 390 kW motor and a variable speed drive. Both are made by Leroy-Somer and power a Vilter single-screw compressor with 1000 kW of cooling capacity. The refrigerant circulated in the system is ammonia. Cooling and heating are simultaneously produced for one-third of the time. To raise the water temperature from 15 to 58°C (with a combined COP of 7.67), the ammonia, after having removed heat from the cold side to produce chilled water, is compressed to achieve the right pressure and temperature. As this temperature is much higher than the usual temperature for a conventional cooling system, the ammonia condenses at 59°C. The water is heated by transferring the heat from ammonia via the condenser and other heat exchangers located at various points in the system for heat optimisation purposes. During the remaining one-third of the time, chilled water is produced conventionally with a COP of 5.75. Ultimately, the system will recover all the heat extracted during the production of chilled water. Chilled water at 1 to 7°C and 200 m3 of hot water at 60°C are produced daily at the plant. To do this, the old system consumed an average of 820 kW of energy per tonne of production per year. With the new system, this level is now only 560 kW. The Dyneo® LSRPM is a range of permanent-magnet synchronous motors incorporating technology patented by Leroy-Somer. The innovative design of the magnet rotor significantly increases efficiency to levels approaching 98%. The low losses of the magnet rotor technology considerably reduce heating of the bearings. As a result, they need to be lubricated much less often and the life of the motor is increased. Vilter is a brand of Emerson Climate Technologies, which employs more than 16,000 people worldwide. Instead of standard twin-screw compressors, the company uses a single-screw compressor. Compression is accomplished by a single screw and two star-shaped gate rotors. The compressor is designed to balance the single screw both radially and axially. This balance ensures that very low loads are placed on the bearings, thus achieving a high level of reliability with considerably reduced vibration and noise levels. Cofely Axima was in charge of managing every aspect of the project, from engineering and installation, to control and supervision (PLC control, instant performance monitoring and traceability of all parameters). Only the electrical wiring was contracted out. La Compagnie des Fromages’ process was down for only 3 hours, during the commissioning phase.

Disclaimer: The information provided within this publication / eBook/ content is for general informational purposes only. While we try to keep the information up-to-date and correct, there are no representations or warranties, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the information, products, services, or related graphics contained in this publication / eBook/ content for any purpose. Any use of this information is at your own risk.

Youth

Youth

Women

Women

Research for Ishrae

Research for Ishrae