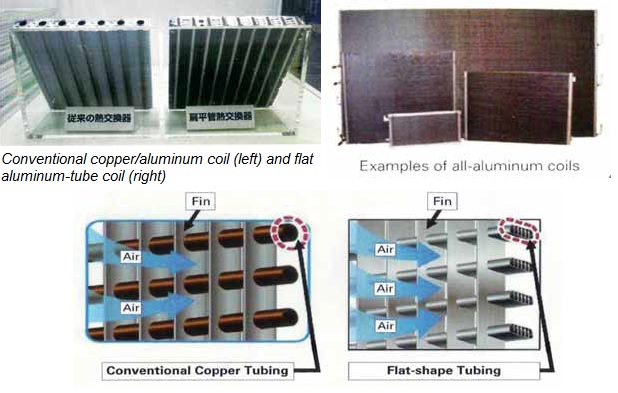

For years, copper tubes with aluminium fins have been the typical choice for condensing coils for HVAC&R equipment. Due to soaring copper prices, however, manufacturers have recently begun looking at adopting aluminium tubes as a way to reduce costs. Aluminium tube/aluminium fin condensing coils have actually been around for decades. As early as the 1970s, U.S.-based General Electric and Bryant, a subsidiary of Carrier, tried to adopt them in outdoor units. However, the brazing of the aluminium tubes and interconnecting piping between the indoor and outdoor units), which is done in the field, posed a particular challenge. In addition, maintenance and repairs when a leak occurred have proven difficult for field service mechanics. For these reasons, all-aluminium heat exchangers have not come into widespread use. All-aluminium heat exchanger coils called microchannel coils were developed around 2008, and Luvata and Delphi, an automotive components manufacturer, have begun selling microchannel heat exchangers. Carrier and other manufacturers then began adopting them in their air conditioning equipment. At present, major Japanese automotive air conditioner manufacturers such as Denso and Sanden, and Chinese manufacturers such as Sanhua and DunAn, are manufacturing allaluminium heat exchangers.

Disclaimer: The information provided within this publication / eBook/ content is for general informational purposes only. While we try to keep the information up-to-date and correct, there are no representations or warranties, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the information, products, services, or related graphics contained in this publication / eBook/ content for any purpose. Any use of this information is at your own risk.

Youth

Youth

Women

Women

Research for Ishrae

Research for Ishrae